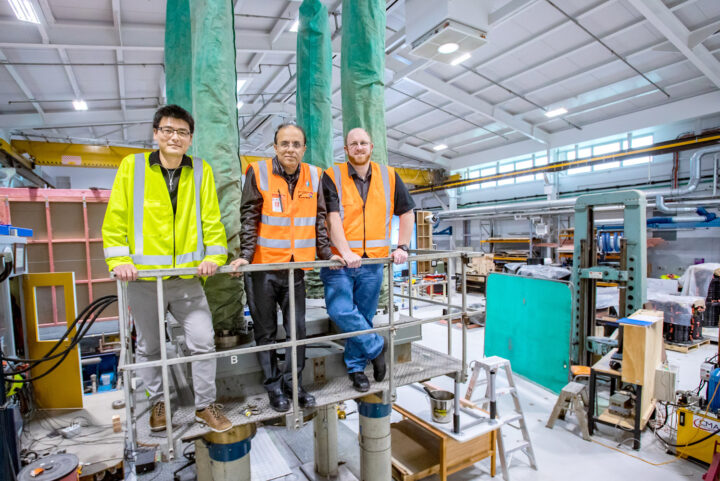

Revolutionising panel construction

New Zealand engineers aim to revolutionise the way we construct buildings with a modular building system that’s fast to assemble, recyclable and could be the answer to earthquake prone communities.

New Zealand engineers aim to revolutionise the way we construct buildings with a modular building system that’s fast to assemble, recyclable and could be the answer to earthquake prone communities. University of Canterbury (UC) Professor Rajesh Dhakal leads a team of industry and academic experts seeking to overcome the shortcomings of traditional concrete buildings and current prefabrication practices.

The Rapid, Reduced-carbon, Resilient, and Recyclable Modular Building System (R4MBS) is made up of prefabricated components which are assembled using low-damage steel connections and positioned without the need of on-site concreting.

The project aims to improve design and construction practice to make future buildings structurally flexible and adaptable enough to meet increased public and industry expectations.

“To meet changing societal demands, the design and construction philosophy for new builds and the maintenance and upgrading of existing buildings needs to evolve,” Professor Dhakal says.

A modular building system can save months of construction time while reducing production waste which brings considerable cost savings and environmental benefits.

R4MBS will provide design and construction guidance making it easy for industry adoption and implementation in new buildings while allowing for ease

of extension and seismic upgrading, if necessary. “Our understanding of seismic risk is improving constantly with new knowledge exposing deficiencies in our existing building environment,” Professor Dhakal says.

“R4MBS buildings will be significantly more resilient in earthquakes than traditional concrete buildings. The low-damage design eliminates the need for repairs on buildings hit by minor to moderate earthquakes while, in the event of a severe earthquake, the modular construction means full repair is possible by replacing only the damaged components.”

R4MBS avoids the vulnerability of precast floors by adopting a novel and smart connection between the floor and the building frames. The floor is prefabricated offsite and assembled on location using low-damage steel connectors, greatly reducing the risk of damage to the floor.

Because the system is modular, there’s no need for demolition as the structure can be partially or fully disassembled for reusable or recyclable components.